Aluminium 6061 vs. Aluminium 6063 are two of the most common aluminum alloys used today. While both are aluminum alloys, Aluminium 6061 vs. Aluminium 6063 differ significantly in strength, appearance, and typical applications. When comparing Aluminium 6061 vs. Aluminium 6063, 6061 is known for its superior strength, whereas 6063 offers a smoother surface finish. The table below highlights these differences:

| Alloy | Aluminum Content (%) | Silicon (%) | Magnesium (%) | Copper (%) | Chromium (%) | Density (g/cm³) | Key Uses |

|---|---|---|---|---|---|---|---|

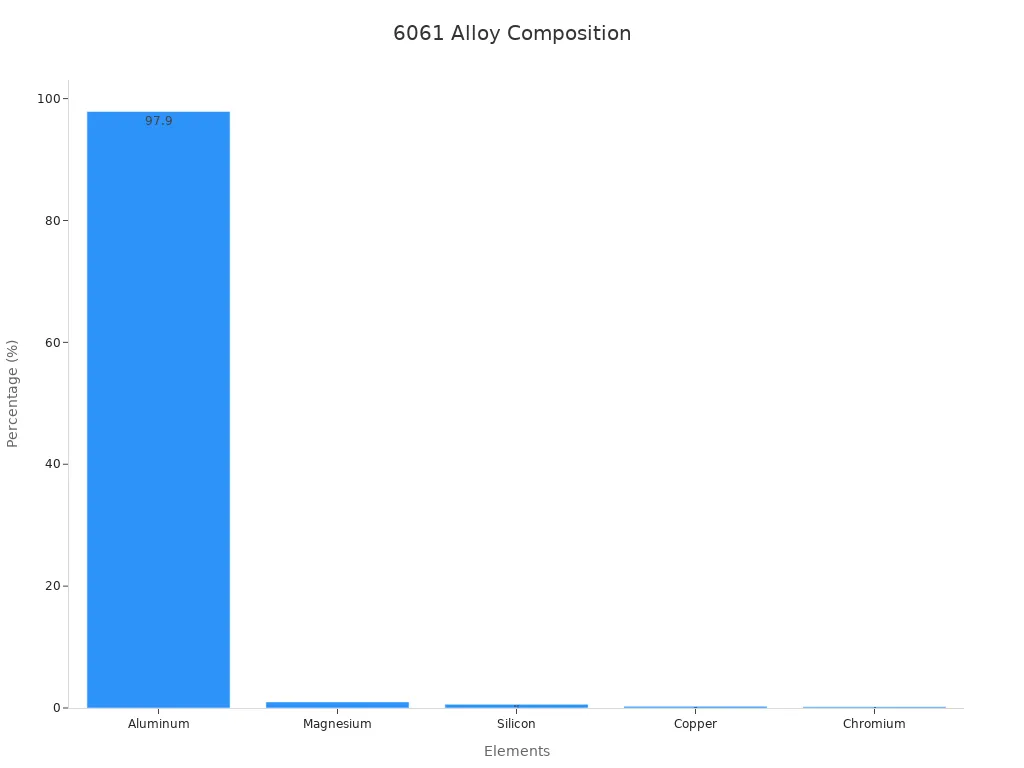

| 6061 | 97.9 | 0.6 | 1.0 | 0.25 | 0.2 | 2.70 | Structural, aerospace |

| 6063 | 98.9 | 0.4 | 0.7 | N/A | N/A | 2.70 | Architectural, decorative |

Both Aluminium 6061 vs. Aluminium 6063 perform well in their respective roles. Aluminium 6061 is ideal for projects requiring higher strength, while Aluminium 6063 is preferred for applications where a smooth, attractive finish is important. Choosing between Aluminium 6061 vs. Aluminium 6063 depends on your specific needs, as each alloy has unique advantages for aluminum alloy projects.

Key Takeaways

- Aluminium 6061 is stronger. It is good for heavy-duty parts. People use it in planes, cars, and bridges.

- Aluminium 6063 has a smoother finish. It is easier to shape. This makes it great for windows and doors. It is also good for decoration.

- 6063 resists rust better. It works well for outdoor projects. 6061 is stronger but may show wear over time.

- 6061 is easier to machine and weld. It is good for making strong parts. 6063 is better for making complex shapes. It gives a clean look.

- You should pick the right alloy for your project. Think about strength, looks, rust resistance, and cost.

Aluminium 6061 vs. Aluminium 6063: Quick Overview

What is aluminum 6061?

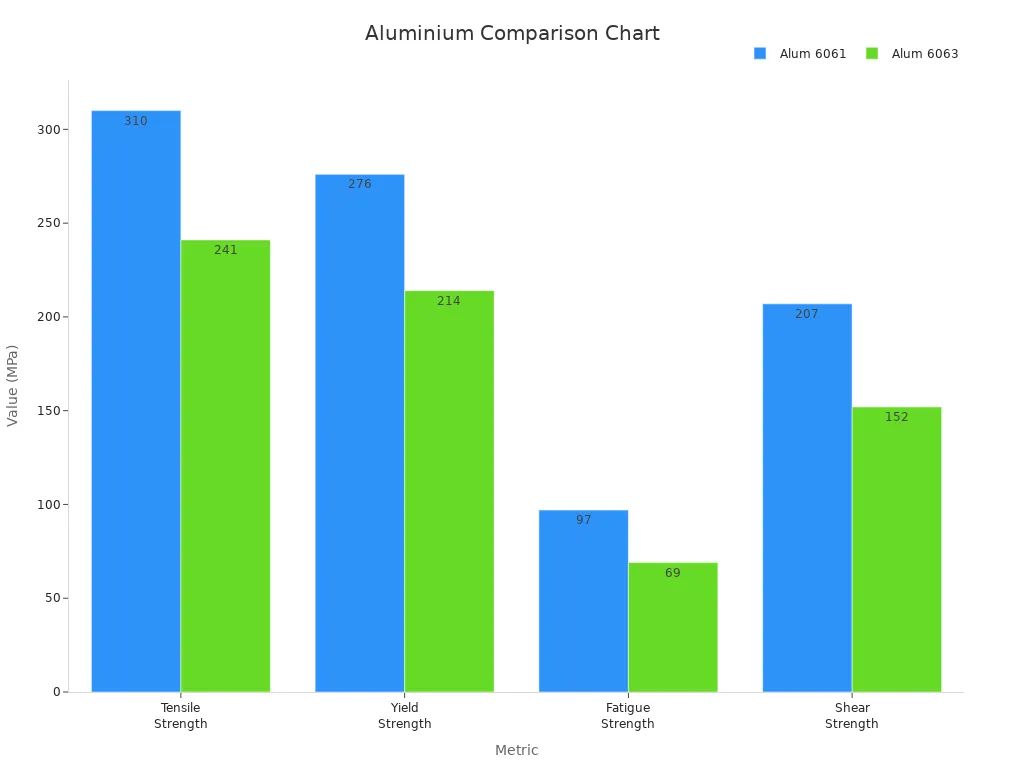

Aluminum 6061 is a strong and useful alloy. It has about 97.9% aluminum. Magnesium and silicon are the main extra elements. This alloy is known for being strong but not heavy. It has good mechanical properties. Its tensile strength is about 310 MPa. Its yield strength is 276 MPa. It also has good fatigue strength. The Brinell hardness is 95. These features make it great for tough projects.

6061 aluminum makes a layer that protects it from rust. It is easy to cut, weld, and shape. Many industries use this alloy. It is used in planes, cars, boats, and buildings. You can heat treat this alloy to make it stronger. The T6 temper is the most common type. It gives a good mix of strength and workability.

Note: 6061 aluminum works well for parts that hold heavy weight.

Here is a chart that shows what is in 6061 aluminum:

What is aluminum 6063?

Aluminum 6063 is another popular alloy. It is best known for its smooth finish. It is also easy to shape. This alloy has about 98.9% aluminum. It has less magnesium and silicon than 6061. Its tensile strength is 241 MPa. Its yield strength is 214 MPa. It is softer and bends more easily than 6061. This makes it simple to make into special shapes.

6063 aluminum is often picked for building and decoration. It does not rust easily, even outside. It also lets heat move through it better than 6061. It melts at a slightly higher temperature. Many window and door frames use 6063 aluminum. It looks nice and is easy to work with.

Tip: 6063 aluminum is best for projects that need a nice look and detailed shapes.

Here is a quick table to compare 6061 and 6063:

| Property / Metric | Aluminum 6061 (T6) | Aluminum 6063 (T6) |

|---|---|---|

| Aluminum Content (%) | ~96.45 | ~98.9 |

| Tensile Strength (MPa) | 310 | 241 |

| Yield Strength (MPa) | 276 | 214 |

| Fatigue Strength (MPa) | 97 | 69 |

| Brinell Hardness | 95 | 73 |

| Elongation at Break (%) | 12 | 15 |

| Thermal Conductivity (W/m-K) | 170 | 200 |

| Melting Point (°C) | 582 – 652 | 616 – 654 |

| Cost | Higher | Lower |

Some quick facts to remember:

- 6061 aluminum is stronger than 6063 aluminum.

- 6063 aluminum has a smoother finish and resists rust better.

- 6061 is best for strong parts. 6063 is better for building looks.

Here is a bar chart that compares the strengths of 6061 and 6063:

6061 vs 6063: Side-by-Side Comparison of Properties

Chemical Composition

Aluminum 6061 and aluminum 6063 are both in the 6xxx series. Their chemical makeup makes them different from each other. The biggest difference is how much magnesium, silicon, copper, and chromium they have. These elements change how the aluminum acts and what it can do.

The table below shows the usual amounts for each element:

| Alloying Element | 6061 (%) Range | 6063 (%) Range |

|---|---|---|

| Manganese (Mn) | 0.0 – 0.15 | 0.0 – 0.10 |

| Iron (Fe) | 0.0 – 0.70 | 0.0 – 0.35 |

| Magnesium (Mg) | 0.80 – 1.20 | 0.45 – 0.90 |

| Silicon (Si) | 0.40 – 0.80 | 0.20 – 0.60 |

| Copper (Cu) | 0.15 – 0.40 | 0.0 – 0.10 |

| Zinc (Zn) | 0.0 – 0.25 | 0.0 – 0.10 |

| Titanium (Ti) | 0.0 – 0.15 | 0.0 – 0.10 |

| Chromium (Cr) | 0.04 – 0.35 | 0.0 – 0.10 |

| Other (Each) | 0.0 – 0.05 | 0.0 – 0.05 |

| Others (Total) | 0.0 – 0.15 | 0.0 – 0.15 |

| Aluminum (Al) | Balance | Balance |

6061 aluminum has more iron, silicon, copper, and chromium. These extra elements make 6061 strong and tough. 6063 aluminum has more pure aluminum and less of these other elements. This makes 6063 smoother and easier to shape.

Note: What is inside the aluminum changes how it works. 6061 is better for strength. 6063 is better for looks and shaping.

Strength and Mechanical Performance

6061 and 6063 have different strengths. 6061 aluminum is stronger and can hold more weight. This makes it good for building strong parts. 6061 gets even stronger when it is heat treated.

6063 aluminum is not as strong as 6061. But it is easier to shape into special forms. That is why people use it for window frames and decorations.

Here is a table that shows how strong each alloy is:

| Property | Aluminum 6061-T6 (approximate) | Aluminum 6063-T6 |

|---|---|---|

| Yield Strength | ~276 MPa (40,000 psi) | 214 MPa (31,000 psi) |

| Ultimate Tensile Strength | ~310 MPa (45,000 psi) | 241 MPa (35,000 psi) |

| Shear Strength | Higher than 6063 | 152 MPa (22,000 psi) |

| Modulus of Elasticity | ~69 GPa (10,000 ksi) | 68.9 GPa (10,000 ksi) |

| Shear Modulus | ~26 GPa (3,740 ksi) | 25.8 GPa (3,740 ksi) |

Some important things to remember:

- 6061 aluminum is stronger than 6063. It is good for heavy jobs and car parts.

- 6063 aluminum is easier to shape. It is great for making special shapes for buildings.

- 6061 has more extra elements. This makes it strong but harder to shape into small details.

Tip: Pick 6061 if you need something strong and tough. Pick 6063 if you want smooth looks and special shapes.

Corrosion Resistance

6061 and 6063 also act differently when it comes to rust. Both make a layer that helps stop rust. But 6063 aluminum usually does better in tough weather.

Studies show that 6061 aluminum can lose some strength after being in city or sea air for a month. Rust starts fast, then slows down as a layer forms. But dirt in the air can hurt this layer. This can cause rust in some spots, especially at the edges. Over time, 6061 can go from bending easily to breaking more easily as it rusts.

6063 aluminum has more pure aluminum and fewer extra elements. This helps it fight rust better. That is why people use it outside for things like window frames and signs. Its smooth surface also helps keep it safe from damage.

Callout: If your project will be outside or get wet, 6063 aluminum is better. It keeps looking good for longer.

Both alloys are useful in different ways. 6061 is best for strength. 6063 is best for fighting rust and looking nice. When choosing between 6061 and 6063, think about what matters most for your project.

Machinability and Workability

Machinability and workability mean how easy it is to cut or shape a material. These things are important when picking 6061 or 6063 for a job.

Aluminum 6061 has more copper, manganese, chromium, titanium, and iron than 6063. Because of this, 6061 is stronger and harder. When you heat treat 6061, it gets even stronger and harder. This makes 6061 great for jobs that need careful cutting. It can be cut faster and gives a nice finish. Many companies use 6061 for parts that must fit just right and have smooth sides.

Aluminum 6063 has less silicon and fewer extra elements. This makes 6063 softer and easier to bend. It is very good for cutting and shaping, especially for making long shapes. Workers can make 6063 into tricky shapes without much trouble. Because it is not as strong, it bends and forms more easily. That is why builders like it for special building shapes.

Tip: Both 6061 and 6063 need fast tools and coolant when cutting. Aluminum can stick to tools, so workers must check for tool damage.

Here is a table that shows how easy it is to cut and shape each one:

| Property / Metric | Aluminum 6061 (T6, T651) | Aluminum 6063 (T6) |

|---|---|---|

| Machinability Rating (0-100) | ~50 | Not explicitly rated, but noted as excellent |

| Yield Strength | 276 MPa (40 ksi) | Lower than 6061 |

| Ultimate Tensile Strength | 310 MPa (45 ksi) | Lower than 6061 |

| Hardness (BHN) | 95 | Lower than 6061 |

| Workability | Good formability, heat treatable | Excellent formability, easy to extrude |

Some things to remember:

- 6061 is best for careful cutting and strong parts.

- 6063 is easier to bend and make into special shapes.

- Both need careful cutting to keep tools from breaking.

Surface Finish and Appearance

How a material looks and feels is important for many projects.

6063 is known for its smooth surface. Builders and designers like 6063 for windows, doors, and trim. Because it has fewer extra elements, it looks bright and clean after shaping. 6063 can also be colored or made shiny, and the look lasts a long time.

6061 has a normal finish and is made for strength, not looks. You can color 6061, but it may not look as smooth or shiny as 6063. Engineers use 6061 when strength matters more than looks, like in frames or machine parts.

Note: If you want something that looks really nice, pick 6063. If you need something strong that people will not see, 6061 is a good choice.

Weldability and Formability

Weldability and formability mean how well a material can be joined or shaped. Both 6061 and 6063 can be welded, but they act a little differently.

| Aspect | Aluminum 6061 | Aluminum 6063 |

|---|---|---|

| Weldability | Good weldability with TIG and MIG; strength near weld drops about 40% but can be restored by heat treatment; filler materials 4043 or 5356 recommended. | Excellent weldability; widely recognized for weldability and heat treatability. |

| Formability | Good workability; can be cast, extruded, rolled, forged; less formable than 6063 for complex shapes. | Excellent for custom extrusions; allows complex shapes with smooth surfaces. |

| Strength | Higher strength; suitable for structural applications; strength can be restored post-welding. | Lower strength; primarily used where visual appeal is prioritized over structural strength. |

| Typical Uses | Structural components requiring strength and weldability. | Architectural and aesthetic applications, such as window and door frames, trims, and tubing. |

You can weld 6061 using TIG or MIG. The area near the weld gets weaker, but you can fix this with heat. This makes 6061 good for strong parts that need to be joined.

6063 is even easier to weld and shape. Workers can make tricky shapes with smooth sides. Many people use 6063 for special shapes that must look good after welding.

Callout: If you need a tricky shape or a smooth look after welding, 6063 is best. If you want something strong and welded, 6061 is the better choice.

Cost and Availability

Aluminum 6061 and aluminum 6063 do not cost the same. They are also not always easy to find in the same way. Builders and factories look at both before they start a job. The price and how easy it is to get each one depends on many things.

Aluminum 6061 costs more than aluminum 6063 most of the time. This is because 6061 is stronger and easier to machine. It takes more work and better materials to make 6061. That makes it more expensive. Aluminum 6063 is easier to shape into long or special pieces. Companies can make 6063 faster and with less work. So, 6063 usually costs less.

Note: If you need lots of special shapes or long pieces, 6063 can help save money.

The table below shows how 6061 and 6063 are different in cost and how easy they are to get:

| Aspect | Aluminum 6061 | Aluminum 6063 |

|---|---|---|

| Cost | Generally more expensive due to higher strength, versatility, and better machinability, which increase production costs. | Usually less expensive because it is easier to extrude and has lower strength, making production cheaper. |

| Price Influences | Market demand, raw material costs, processing fees, supply chain conditions, economic events. | Same factors affect price fluctuations similarly. |

| Machinability | Superior machinability; preferred when machining is a primary concern. | Machinable but less so; better known as an extrusion alloy. |

| Extrudability | Good workability but less ideal for extrusion compared to 6063. | Excellent extrudability and surface finish, favored for architectural profiles. |

| Typical Applications | Aircraft frames, truck frames, chemical equipment, electronic components, fasteners, heat exchangers, marine frames. | Architectural products, construction extrusions, furniture, medical and automotive parts, tubing. |

Both types can change in price for the same reasons. These reasons are things like demand, the price of raw aluminum, and world news. If more people want strong parts, 6061 might cost more. If builders need more window frames or decorations, 6063 might get more expensive.

Aluminum 6061 is used in many jobs. Airplane, truck, and boat makers use it because it is strong. When lots of people need it, it can be hard to find. Aluminum 6063 is used a lot in building and furniture. It is easy to shape, so companies can make a lot of it quickly.

Tip: If your project needs many special shapes or long, smooth pieces, aluminum 6063 is often cheaper and easier to get.

Aluminum 6061 vs. Aluminum 6063: Practical Applications

Common Uses for 6061 aluminum

6061 aluminum is used in many industries. It is strong and lasts a long time. Engineers pick 6061 for parts in planes and cars. It is also used in big machines. Truck frames and boat parts often use 6061. People use it for bike frames too. This alloy is light but very strong. That is why it is good for parts that hold weight. Builders use 6061 for bridges and towers. It is also used for machine parts that must handle stress. 6061 gives good service and does not break easily.

Note: You can heat-treat 6061 aluminum to make it even stronger. This helps it work well in tough places.

Common Uses for 6063 aluminum

6063 aluminum is picked when looks and shape are important. Builders use 6063 for windows and doors. It is also used for curtain walls in buildings. This alloy has a smooth surface. That makes it great for trim and electronics. 6063 is easy to shape into special forms. It is used for furniture, signs, and displays. 6063 does not rust easily, so it works well outside. Many companies use 6063 for things that must look nice and work well.

Tip: 6063 aluminum is best for projects that need fancy shapes and a clean look.

Why choose 6061 or 6063 for your project?

You should pick 6061 or 6063 based on what you need. 6061 is harder and stronger than 6063. It is best for building and heavy jobs. If your project needs to hold a lot of weight, use 6061. 6063 is better for making special shapes and smooth surfaces. It is more pure, so it fights rust better. That is why 6063 is used in buildings and decorations.

The table below shows how each alloy fits different needs:

| Project Need | 6061 | 6063 |

|---|---|---|

| Strength | High | Moderate |

| Formability | Good | Excellent |

| Surface Finish | Good | Superior |

| Typical Applications | Structural, industrial | Architectural, decorative |

Callout: Pick 6061 if you need something strong and tough. Pick 6063 if you want special shapes and a smooth finish.

How to Pick the Right Alloy: 6061 vs 6063

Main Things to Think About

Picking between aluminum 6061 and aluminum 6063 is important. Each one is good for different jobs. Builders and engineers look at many things before they choose.

Here is a table that shows the main things to compare:

| Factor | Aluminium 6061 (T6) | Aluminium 6063 (T6) |

|---|---|---|

| Tensile Strength | About 310 MPa | About 228 MPa |

| Yield Strength | About 276 MPa | About 186 MPa |

| Elongation | Around 10% | Around 12% |

| Fatigue Strength | About 97 MPa | About 76 MPa |

| Corrosion Resistance | Good, works well in tough places | Great in mild places, even better with anodizing |

| Thermal Conductivity | Medium | Higher, good for heat sinks |

| Machinability | Easier to machine, good for careful parts | Smoother finish, easier to make tricky shapes |

| Weldability | Good, works for strong parts | Okay, but not for heavy welds |

| Formability | Medium | Great, best for building shapes |

| Typical Applications | Strong parts, boats, planes, cars | Building frames, decorations, heat sinks |

| Cost Considerations | Usually costs more, stronger | Usually costs less, good for looks and shapes |

When picking an alloy, people should think about these things:

- How strong the part needs to be. Aluminum 6061 is stronger and good for heavy jobs.

- Where the part will be used. Aluminum 6063 fights rust better in easy weather and looks nice after anodizing.

- The shape and design of the part. Aluminum 6063 is easier to make into tricky shapes and has a smoother finish.

- If the part needs to move heat away. Aluminum 6063 lets heat move faster, so it is good for heat sinks.

- How much the material costs. Aluminum 6063 is cheaper and picked for decorations or buildings.

- What kind of cutting or shaping is needed. Aluminum 6061 is better for careful cutting, while aluminum 6063 is better for bending and forming.

Tip: Always pick the alloy that matches what your project needs. This keeps things safe, works well, and saves money.

Example Projects and Which Alloy to Use

Different jobs need different alloys. Here are some common jobs and which alloy is best:

| Property/Aspect | Aluminium 6061 | Aluminium 6063 |

|---|---|---|

| Tensile Strength | Medium to high, about 241-310 MPa | Medium, about 186-290 MPa |

| Yield Strength | Higher than 6063 | Lower than 6061 |

| Corrosion Resistance | Good, but not as good as 6063 | Better at fighting rust |

| Machinability | Good for cutting and welding | Okay for cutting, great for making shapes |

| Surface Finish | Good finish | Very smooth finish, easy to color |

| Electrical Resistance | 0.0365 to 0.043 Ω·mm²/m | A little lower, about 0.035 Ω·mm²/m |

| Thermal Conductivity | 154 to 180 W/m·K | Higher, about 200 to 209 W/m·K |

| Typical Applications | Strong parts: planes, cars, big frames | Building parts: windows, doors, furniture |

Scenario 1: Building a Bridge or Heavy Frame

Engineers use aluminum 6061 for bridges, towers, or big frames. This alloy is strong and keeps things safe for a long time. It also works well in tough weather or near the sea.

Scenario 2: Making Window Frames or Trim

Makers pick aluminum 6063 for window and door frames or trim. This alloy is easy to shape into special forms. It also gives a shiny, smooth look that is nice for buildings.

Scenario 3: Making Heat Sinks or Electronic Parts

Aluminum 6063 is good for heat sinks and parts that need to move heat away. Its higher thermal conductivity helps keep electronics cool.

Scenario 4: Making Car or Plane Parts

Car and plane makers use aluminum 6061 for parts that must be strong and handle stress. This alloy is easy to cut and weld, so it is a top pick for these jobs.

Scenario 5: Making Outdoor Furniture or Railings

Outdoor furniture and railings often use aluminum 6063. This alloy does not rust easily and keeps looking good. It also lets builders make creative shapes.

Note: The best alloy depends on what matters most for your project. If you need strength and toughness, aluminum 6061 is better. If you want a nice look, good rust resistance, and special shapes, aluminum 6063 is best.

Both alloys work for many jobs. The choice depends on what your project needs most. Always check what is needed for strength, rust resistance, looks, and cost before you decide.

Aluminum 6061 and 6063 are not the same. 6061 is stronger than 6063. 6063 is easier to bend and shape. 6061 is good for tough jobs. 6063 is better for making tricky shapes. 6061 has a good finish, but 6063 looks even nicer. The table below shows how they are different:

| Aspect | Aluminium 6061 | Aluminium 6063 |

|---|---|---|

| Strength | Higher | Slightly lower |

| Formability | Moderate | Superior |

| Finishing Quality | Good | Excellent |

| Best Use | Heavy-duty structures | Complex profiles |

Engineers pick 6061 when they need strong parts. They use 6063 when they want smooth looks and special shapes. Picking the right alloy helps keep projects safe and working well.

FAQ

What makes aluminum 6061 stronger than 6063?

Aluminum 6061 contains more magnesium and silicon. These elements increase its strength. Engineers use 6061 for parts that must handle heavy loads. The extra elements also make 6061 harder than 6063.

Can you weld both 6061 and 6063 alloys?

Yes, both alloys can be welded. 6061 needs special care during welding because the area near the weld can weaken. 6063 welds easily and keeps a smooth finish. Always use the right filler material for best results.

Which alloy is better for outdoor use?

6063 works better for outdoor projects. It resists corrosion and keeps its smooth look. Builders often choose 6063 for window frames, railings, and signs. 6061 also resists rust but may not look as nice over time.

Is aluminum 6063 cheaper than 6061?

Yes, aluminum 6063 usually costs less. It is easier to shape and produce. Manufacturers often pick 6063 for large projects that need many custom shapes. 6061 costs more because it is stronger and harder to machine.

Can you anodize both 6061 and 6063?

Both alloys can be anodized. 6063 gives a brighter and smoother finish after anodizing. This makes it popular for decorative parts. 6061 can also be anodized but may not look as shiny or smooth as 6063.