Aluminum profiles are important parts in building and industry today. Manufacturers shape aluminum profiles to make strong and light frames. These frames help support windows, doors, and curtain walls. In 2024, the world market for aluminum and aluminum profiles was $56.39 billion. This happened because people want materials that are light, last long, and are good for the environment. Asia Pacific makes the most aluminum profiles. Cities are growing fast there, which helps the market grow. Builders pick aluminum profiles because they save money and do not rust easily. People use them for many things, like:

- Framing for windows, doors, and partitions

- Beams and columns in lightweight projects

- Curtain walls for weather protection and looks

- Strong, energy-saving windows and railings

Aluminum profiles are easy to design in many ways. They help make buildings save energy. This is why people all over the world like to use aluminum in construction.

Key Takeaways

- Aluminum profiles are strong and light. They do not rust. This makes them great for building and industry.

- There are many shapes like hollow beams, square tubes, and T-sections. Each shape is used for a special job in building or factories.

- Ways to make them, like extrusion and anodizing, make them stronger. These ways also help them look better and last longer.

- Aluminum profiles help save energy and money over time. They are easy to recycle, so they help the environment.

- Modular aluminum systems let people build fast and change things easily. This helps projects finish faster and work better.

Aluminum Profiles Overview

What Are Aluminum Profiles

Aluminum profiles are special shapes made from aluminum. Manufacturers use extrusion to make these shapes. There are many types, like hollow beams, L-shaped angles, channels, flat bars, I beams, and T bars. Each type has its own job in building and industry. Aluminum profiles are light and strong. They are also easy to shape. Their strength-to-weight ratio is high. This makes them good for frames in buildings, windows, doors, and curtain walls.

Architectural aluminum profiles look nice and seal well. They do not catch fire easily. Some common shapes are round tubes, square tubes, rods, and channels. Manufacturers make sure these profiles meet tough standards. This helps them last long and handle bad weather. The surface can be anodized, powder coated, or brushed. These finishes make them look better and protect them. Most profiles use alloys like 6061 for strong parts and 6063 for building looks.

Note: Aluminum and aluminium profiles must follow rules like GB5237, EN12020-2, and ANSIH35.2. These rules make sure the profiles are good quality, the right size, and work well in different places.

Importance in Industry

Aluminum profiles are important in many industries. Because they are light, finished products weigh less. This helps cars and planes use less energy. Aluminum profiles are strong. They help support car frames and window frames in buildings. They do not rust, so they last a long time. This is good for things like solar panel frames and wind turbine blades.

| Feature/Benefit | Description | Industrial Application Examples |

|---|---|---|

| Lightweight | Makes products lighter and more efficient | Cars, airplanes |

| High Strength | Strong for how light it is | Car frames, window frames |

| Corrosion Resistance | Lasts long even in tough places | Solar panels, wind turbines |

| Flexible Processability | Can be made into many shapes | Electronics, furniture |

| Cost-Effectiveness | Saves material and money | Making lots of cars, buildings |

| Sustainability | Can be recycled and is good for the planet | Renewable energy parts |

Aluminum extrusion lets companies make special shapes. These shapes help products work better. Automation and AI help make things faster and with less waste. They also make the quality better. Aluminum profiles help new ideas in electronics, green energy, and transport. This makes them very important for today’s industry.

Different Types of Aluminum Profiles

Aluminum profiles have many shapes and jobs in building and industry. Companies use different ways to make them, like hot extrusion, cold extrusion, and indirect extrusion. Each way shapes the aluminum for a special use. You can sort aluminum profiles by how they are made, their shape, or what they do.

Hollow Beam

Hollow beam profiles are good for light building frames. These profiles have a hole in the middle. This makes them lighter but still strong. Engineers use hollow beams for window frames and curtain walls. They also use them for supports that hold medium weights. The oxide layer on aluminum helps stop rust. Hollow beams are easy to design with. This makes them great for parts that need to look nice and work well. But for big bridges, people use steel beams because they are stronger.

Tip: Hollow beam aluminum profiles are best where saving weight and stopping rust are more important than holding heavy things.

Square Profile

Square profiles are used a lot in building. Their simple shape makes them easy to use in many ways. These profiles come in set sizes. This helps builders pick the right one for each job.

| Size (mm) | Typical Applications |

|---|---|

| 20×20 | Small, lightweight frames and structures |

| 30×30 | Medium-sized frames and supports |

| 40×40 | Larger frames and structural parts |

| 50×50 | High-strength, demanding applications |

| 80×80 and up | Heavy-duty support in industrial frameworks |

Companies use square aluminum profiles for machine frames and covers. They also use them for green energy projects. The even size and strong corners make them good for light and heavy jobs.

SD Aluminum Profile

SD aluminum profiles are a main group of extruded aluminum profiles. They use alloys like 6061 or 6063. These alloys give a good mix of strength and looks. SD profiles do not have special shapes. But they are still a top pick for many building jobs. They fit into many frames and support systems.

RCW Profile

RCW profiles are special for curtain wall systems. These profiles help hold big glass panels on buildings. RCW profiles must be strong, light, and stand up to weather. Their shape makes it easy to put glass in and keep it safe. This is why they are important for modern building fronts.

Door Section

Aluminum profiles for doors are made to be strong and safe. Companies use extrusion to make shapes that hold heavy glass but stay slim. The aging step in making them makes them stronger and more bendy. These profiles do not rust, so they last in bad weather. Door profiles often have spots for locks to make them safer. Builders use screw holes, snap fits, and joints to put them together fast and tight.

Note: Aluminum profiles for doors often have thermal breaks and special coatings to save energy and last longer.

Louver Profile

Louver profiles are important in new building designs. These profiles let slats move to control air and sun. Aluminum louver profiles help air move in buildings. This can lower the need for air conditioning. They also keep out rain, dust, and bugs. Architects like louver profiles because they look nice and come in many colors. Louvers can go sideways or up and down. They give privacy and cool looks while saving energy.

T-Section

T-section profiles are key in modular building systems. These profiles have a T-shape with slots for connectors. T-section profiles are strong for their weight and do not rust because of coatings. Their design lets builders put things together, change, or move them without welding. T-section profiles are used for work tables, machine frames, and moving systems. They come in light and heavy types for different needs.

- Common uses for T-section profiles:

- Machine frames and bases

- Industrial workstations

- Equipment enclosures and guards

- Conveyor and material handling systems

- Modular office and workshop furniture

Main Types of Aluminum Profiles

Companies make several main types of aluminum profiles by how they are made:

- Extruded aluminum profiles: Made by pushing hot aluminum through a mold to get a shape. Most building profiles are this type.

- Anodized profiles: Treated with electricity to stop rust and look better.

- Die-cast profiles: Made by pouring melted aluminum into a mold for tricky shapes.

- Rolled profiles: Made by rolling aluminum to get thin, flat pieces.

- Sheet, diamond plate, and tread plate profiles: Used for floors, stairs, and places that need grip.

Classification by Shape and Function

You can sort aluminum profiles by their shape and what they do:

- Solid profiles: No holes, like beams, rods, and angles. Used for basic support.

- Hollow profiles: Have empty spaces, like tubes and hollow beams. They save weight and are easy to design with.

- Semi-hollow profiles: Have some openings, so they balance strength and weight.

Profiles can be standard or custom. Standard profiles are common shapes like T-tracks, U channels, and Z profiles. Custom profiles have special shapes for certain jobs in building, cars, or factories.

Modular Systems and Specialized Lines

Many companies use modular aluminum profile systems for easy building. These systems have lines like Line 5, Line 6, and D30. Each line has different slot sizes and strengths for different jobs. Modular systems let you change or add parts fast. This is good for factories, robots, and custom work areas.

Callout: The many types of aluminum profiles help builders and engineers make strong, light, and good-looking things for any job.

Aluminum Manufacturing Processes

Extrusion

Aluminum extrusion shapes aluminum into profiles with exact cross-sections. First, engineers make a mold called a die for the profile. Workers heat the aluminum billet until it is soft. They push the billet through the die to form the shape. The new profile cools down to stay strong. Stretching makes the profile straight and removes stress. Cutting gives each profile its final size. Heat treatment like T5 or T6 makes it stronger. Finishing steps such as anodizing or powder coating protect the surface and make it look nice.

Key Steps in Aluminium Extrusion:

- Die preparation

- Billet preheating

- Extrusion through the die

- Controlled cooling

- Stretching

- Cutting to length

- Heat treatment

- Surface finishing

Aluminum extrusion lets people design many shapes. The profiles are light but strong and last a long time. Companies use this process for window frames, door frames, and curtain walls. This method is good for making many products fast. It is also better for the planet because aluminum can be recycled.

Anodizing

Anodizing uses electricity to make a tough oxide layer on aluminum profiles. This layer stops rust and damage. It keeps water, salt, and bad weather away from the aluminum. The anodized surface can be colored in many ways. This gives builders choices for how things look. The color stays bright and does not peel or chip. Anodized aluminum profiles need less care and last longer outside.

Tip: Anodized finishes help railings and building parts last longer and give better grip.

Die Casting

Die casting makes aluminum profiles by putting hot, melted aluminum into a steel mold. This way, workers can make tricky shapes that fit together well. Die-cast aluminum parts are used for strong frames and covers in machines. The process makes profiles that are light, strong, and do not rust. Companies pick die casting for machine parts that need special shapes and strength.

Rolling

Rolling shapes aluminum sheets into profiles with big rollers at room temperature. Good aluminum alloys make the profiles stronger and stop rust. Rolling makes profiles that are strong for their weight. This is important for buildings. The look of the surface depends on what is done after rolling, like anodizing or powder coating. These steps make the profiles last longer and look better.

| Process Step | Effect on Aluminum Profile |

|---|---|

| Rolling | Shapes and strengthens the profile |

| Surface Treatment | Improves appearance and durability |

Embossing and CNC

Embossing presses patterns onto aluminum profiles for looks or special uses. CNC machining uses computers to control tools that cut and shape aluminum very exactly. Aluminum is easy to work with and strong for its weight. This makes it great for CNC jobs. Companies use CNC to make custom profiles for planes, cars, and factories. After machining, anodizing or powder coating helps stop rust and makes them look nice.

- Benefits of CNC and Embossing:

- Custom shapes are easy to make

- Profiles last longer

- Many finishes and colors are possible

- Making lots of profiles is cheaper and better for the planet

Note: CNC machining helps make tricky designs and keeps quality the same when making many parts.

Properties of Aluminium Profiles

Physical and Mechanical

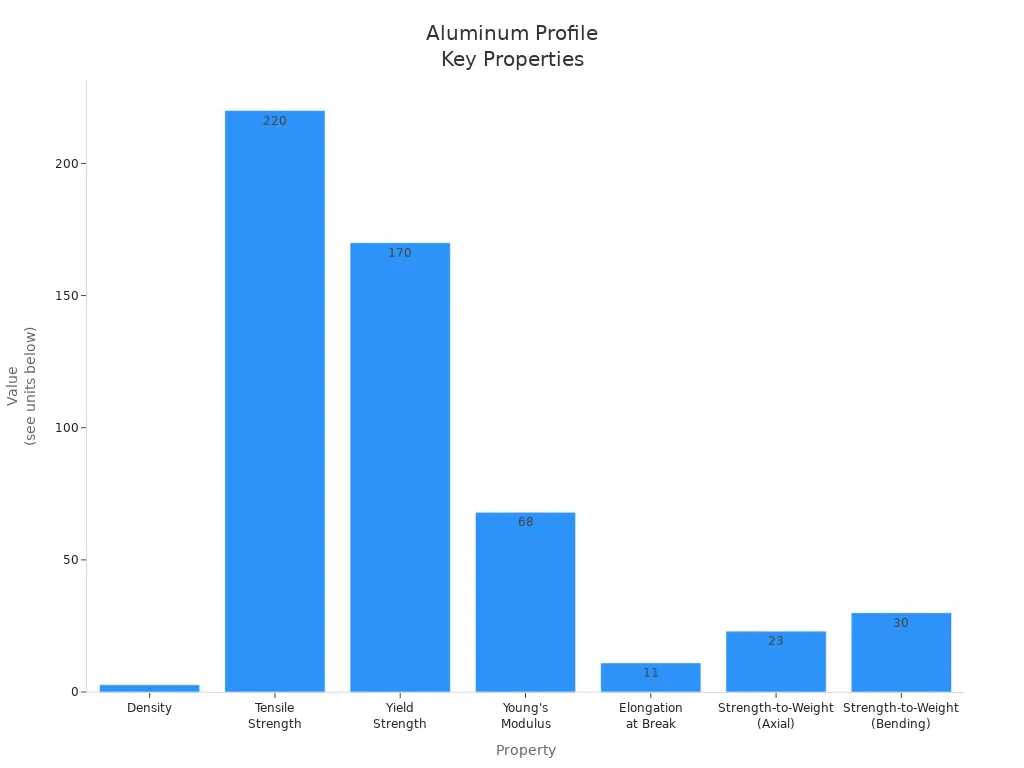

Aluminum profiles have great physical and mechanical properties. They are light because they have low density. This makes them easier to move than steel. Engineers can build big frames that are easy to carry and put together. Aluminum has a high strength-to-weight ratio. It can hold heavy things but does not weigh much. Alloys like 6060-T6 are strong and flexible.

| Property | Value |

|---|---|

| Density | 2.7 g/cm³ |

| Tensile Strength (UTS) | 220 MPa |

| Yield Strength | 170 MPa |

| Young’s Modulus | 68 GPa |

| Elongation at Break | 11% |

| Strength-to-Weight (Axial) | 23 points |

| Strength-to-Weight (Bending) | 30 points |

Aluminum profiles can bend and stretch without snapping. This helps them take hits and not break. The chart below shows how aluminum stacks up against other materials.

Corrosion Resistance

Aluminum makes a natural oxide layer that stops rust. This keeps it safe from water and bad weather. Aluminum is great for outdoor and sea places. Carbon steel needs extra coatings to stop rust. Aluminum does not need these coatings. Stainless steel also fights rust but is heavier and costs more. Galvanized steel uses zinc to protect it but still needs care. Aluminum’s resistance means less fixing and longer life in tough places.

Tip: Aluminum profiles are good for railings, window frames, and building fronts. They stay strong and look nice for a long time.

Design Flexibility

Aluminum profiles are easy to design with. Extrusion lets makers create many shapes. You can get simple beams or special custom profiles. Standard shapes include hollow beams, angles, channels, and flat bars. Custom profiles can have round corners and even walls for better looks and strength.

- Key design advantages:

- T-slot profiles make it easy to put things together.

- Modular systems let you change size or layout fast.

- Custom profiles mean fewer extra parts, saving time and money.

Aluminum is easy to work with. Architects and engineers can make cool and useful buildings. This helps new ideas in building and industry.

Sustainability

Aluminum profiles are good for the planet. They can be recycled many times. Over 90% of aluminum gets recycled in some industries. Recycling aluminum uses much less energy than making new metal. This saves resources and cuts pollution. Aluminum helps buildings save energy by bouncing back solar heat and giving insulation. Factories now use more clean energy to make aluminum.

- Sustainability highlights:

- Aluminum is about 25% of all metals used in building.

- Over 80% of aluminum made in the U.S. is recycled.

- Recycling saves millions of barrels of oil every year.

Note: Using aluminum profiles helps green building and makes things last longer.

Applications of Aluminum Profiles

Construction Uses

Aluminum profiles are very important in building today. Builders use them for frames, facades, windows, and doors. Aluminum is light, so workers can move it easily. It is strong enough to hold big glass and heavy things.

- Aluminum skirting keeps walls safe from water and damage. It lasts longer than wood and is cheaper to care for.

- Roofs use aluminum profiles because they do not rust. These roofs can have many shapes and last a long time with little work.

- Aluminum cladding panels stop fire and look nice. They also help keep buildings warm or cool.

- Window and door frames use special aluminum profiles. These frames hold big glass and stay steady. Builders can pick sliding, casement, fixed, or tilt-turn styles. Some frames have thermal breaks to save energy.

- Curtain walls use aluminum profiles for strength and design. These walls keep out bad weather and make buildings look cool.

| Application | Key Benefits | Common Examples |

|---|---|---|

| Window & Door Frames | Strong, easy to care for, stylish | Homes and office buildings |

| Curtain Walls | Light, tough, looks good | Tall offices, public buildings |

| Roofing & Cladding | Rust-proof, light | Factories, new houses |

| Scaffolding | Strong but not heavy | Building sites |

| Interior Fittings | Easy to design, lasts long | Office walls, trim |

Tip: Using aluminum profiles makes buildings lighter, faster to build, and cheaper over time.

Architecture Uses

Aluminum profiles help shape how buildings look and work. Designers use them for fancy walls, ceilings, and curved shapes. Aluminum bends into many shapes for style and use.

- Architects use profiles for windows, curtain walls, roofs, skylights, canopies, railings, and handrails.

- Aluminum profiles mix with glass and wood to look better. This makes spaces special and friendly.

- Finishes like brushed, polished, anodized, or powder-coated give many style choices.

- Aluminum is light, so it is quick to put in and easy to clean. This helps in busy places like airports and malls.

- Profiles help save energy and make buildings comfy by keeping heat and noise out.

Callout: Aluminum profiles let architects make buildings that look great and work well for city life.

Industrial Applications

Factories use aluminum profiles for many jobs. These profiles are the main parts of machines and moving systems.

- Factories use T-slot profiles for robot arms, conveyor frames, and machine bases. The design lets workers change things fast.

- Safety guards and work areas use aluminum profiles for barriers. Workers can move or change these as needed.

- Storage racks, carts, and frames use aluminum for moving things around.

- Custom profiles make workstations comfy and help people work better.

- Labs use aluminum profiles to build test setups. The parts are easy to change for new tests.

- Aluminum plates make strong bases for robots and machines.

- Conveyor systems use aluminum for frames and rails.

- Cleanrooms and medical tools use smooth aluminum profiles for easy cleaning.

Note: Aluminum profiles in factories are easy to design, light, and strong. These features help work go faster and bring new ideas.

Specialized Applications

Some aluminum profiles are made for special places like labs, trains, and big projects.

- Cleanroom profiles are smooth and fight rust. They hold panels, ceilings, windows, and doors. These profiles help keep places clean and safe.

- In bridges and trains, aluminum profiles do not rust and last long. They hold walkways, railings, and decorations.

- Airports use aluminum profiles in terminals, jetbridges, and baggage systems. These profiles meet fire rules and last for years.

- Highways use aluminum for sound walls, signs, and guardrails. The light weight makes them quick to put in and strong against weather.

- Docks and piers use aluminum profiles because they do not rust in saltwater and can hold heavy loads.

| Infrastructure Type | Application Examples | Durability and Performance Benefits |

|---|---|---|

| Cleanrooms | Panels, ceilings, windows, doors | Stops germs, fights rust, easy to clean |

| Bridges | Walkways, railings, decor | Fights salt, lasts in tough weather |

| Railways | Canopies, station frames | Needs little care, saves money, strong |

| Airports | Terminals, jetbridges, baggage | Safe from fire, lasts a long time |

| Highways | Sound barriers, guardrails | Handles weather, fast to install |

| Marine | Docks, piers | Fights saltwater, stays strong |

Callout: Special aluminum profiles are made to be safe, clean, and tough for hard jobs.

Selecting Aluminum Profiles

Application Needs

Picking the right aluminum profile means knowing what your project needs. Engineers look at many things to keep projects safe and working well. They pick aluminum grades for how strong they need to be. Strong grades like 2024 or 7075 are good for heavy jobs. Grades like 6061 or 5052 work for lighter frames and are easy to shape. If the place is wet or outside, corrosion resistance is important. Grades like 6061 and 5052 help stop rust. Some grades, like 3003 and 5052, bend into tricky shapes without breaking. Weldability matters too. Grades like 5083 and 6061 weld easily, but some need special ways to join. How the profile looks also matters. Surface treatments like anodizing or powder coating change how it looks and how much it costs.

Tip: Always pick the aluminum profile that fits the job’s strength, weather, and how it connects to other parts.

Durability and Cost

Durability and cost decide how good aluminum profiles are over time. Aluminum is light but strong. This means buildings are not as heavy and moving parts costs less. Its oxide layer keeps it from rusting, so it works well outside and needs less fixing. Aluminum profiles help save energy because they keep heat and sound in or out. Aluminum can cost more at first than steel. But it saves money later because it needs less care, saves energy, and can be recycled. Good profiles with the right weight and finish cost more at first, but save money in the long run.

| Aspect | Explanation |

|---|---|

| Lightweight & Durability | Makes buildings lighter and easier to move, but still strong. |

| Corrosion Resistance | Stops rust, lasts longer, and needs less fixing. |

| Energy Efficiency | Keeps heat and sound in or out, saving energy. |

| Cost Considerations | Costs more at first, but saves money later. |

| Aesthetic & Customization | Coatings make profiles look nice and fit building styles. |

| Investment Justification | Good profiles last longer and save money over time. |

Design and Modularity

Aluminum profiles are easy to design and change. Modular systems let builders put things together fast without welding or painting. You can cut, drill, and join profiles to fit new needs. Good manufacturing makes sure parts fit together well. There are many profiles and accessories to pick from, so you can make them work for lots of jobs. Modular profiles make it easy to swap parts and change designs. This means less waiting and work stops less often on big projects.

- Modular aluminum profiles:

- Let builders change things fast when projects need it.

- Save money over time because they change easier than welded steel.

- Can be customized for how things work or look.

- Make it easy to add, change, or reuse parts.

- Help finish projects faster by cutting down wait times.

Callout: Modular aluminum profile systems help engineers and builders change plans quickly when projects need something new.

Aluminum profiles are very important in building and factories today. Picking the right profile helps make things strong and last longer. You need to know how profiles are made to get good results. Here are some main ideas:

- Using the right profile for each job makes things work better in building, cars, and making products.

- Learning how profiles are made and checked helps them last longer and saves money.

- Working with makers early helps stop mistakes and makes projects go well.

| Feature | Benefit |

|---|---|

| Lightweight | Makes moving and putting in profiles faster and cheaper |

| Corrosion Resistance | Needs less fixing and lasts longer |

| Recyclability | Helps the planet and cuts waste |

Picking the best aluminum profiles helps projects finish faster, cost less, and be better for the environment.

FAQ

What are the main benefits of using aluminum profiles in construction?

Aluminum profiles are strong and light. They do not rust easily. Builders can shape them for many jobs. These profiles help make buildings lighter. They also lower the cost to fix things.

Can aluminum profiles be recycled?

Yes, aluminum profiles can be recycled many times. Recycling does not make them weaker. It saves energy and helps the planet. Recycling is good for green building.

How do manufacturers finish aluminum profiles for better durability?

Manufacturers use anodizing and powder coating. These finishes protect the surface from rust and damage. They also make profiles look better. The finishes help profiles last longer.

Are aluminum profiles suitable for outdoor applications?

Aluminum profiles work well outside. Their oxide layer and finishes stop weather and water. Sunlight does not hurt them. They are great for windows, doors, and building fronts.

What shapes do aluminum profiles come in?

Aluminum profiles come in many shapes. Some are T-sections, hollow beams, and square tubes. There are also custom shapes. Each shape is made for a special job or look.